Impressive!!

Today, you are going to learn and know how impressive operating Heavy Machinery is!

Most people in Uganda, Congo, Burundi, Rwanda, South Sudan and more think operating heavy machinery is just about pulling levers and moving earth.

But let me tell you it’s much more than that. It’s about focus, timing, responsibility, and skill.

So if you’re curious about what really goes into training for heavy machinery operation, or you’re thinking of joining this field, this post is for you.

Lesson 1: Confidence Comes After the Chaos

In your first week you will learn a lot which will help you gain confidence that comes after the chaos.

Unlike my first week of training? Total chaos. I couldn’t remember which lever lifted the arm or turned the bucket. I moved too fast and nearly drove the backhoe into a trench. Embarrassing, right? But every pro operator I met had a similar story.

You may either go through the same or not. It will depend on you while you are training during that time.

The key is persistence and hands-on practice. After a few days, your hands may stop shaking, after a few weeks, you will be controlling the machine like it was an extension of your body.

Why this matters:

• Confidence grows with practice

• Mistakes are part of the process

• Muscle memory is real training makes it second nature

Lesson 2: The Real Power Is in Precision

Let me tell you something you’ll never forget. “It’s not about how fast you move dirt. It’s about how smart you move it.” And that’s the fact.

During training, you learn that precision is more valuable than speed. Whether you’re using an excavator, bulldozer, or grader, every inch matters. Precision saves fuel, reduces machine wear, and gets the job done right the first time.

What you’ll master:

• Smooth, calculated movements

• Avoiding rework and wasted fuel

• Controlling load, depth, and angle

Lesson 3: Safety is Not Optional, It’s Life-Saving

Let me be honest with you before doing any training, you may think safety talks were just for show. But then we had a close call, one of our team members didn’t do a walk-around check.

His excavator had a loose hydraulic line. As he lifted a heavy load, the line burst, and the arm dropped suddenly. Thankfully, no one was hurt.

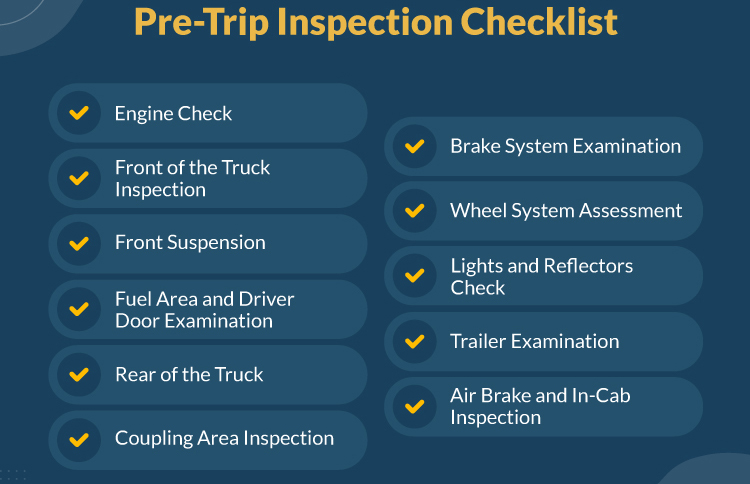

But it could have been much worse, since that day, So my point is never skip any safety checks. Safety Training Covers the following; pre-operation inspections, load limits and stability spotter communication and emergency stops

Lesson 4: Communication Saves More Than Just Time

Here you will learn how communication is key in machinery operation.

Now one of the dump truck driver was supposed to reverse into position but he had no radios, didn’t give a signal. and ended up scraping someone’s bumper.

This is to set your mind while we will be training you the proper hand signals, radio codes, and always confirmed directions before moving. A simple “Are we clear?” could save thousands in damages.

• Communication essentials you’ll learn:

• Hand signals for guiding and stopping

• Radio etiquette and clear commands

• Working smoothly with spotters and ground crews

Lesson 5: You Don’t Just Operate the Machine, You Protect It

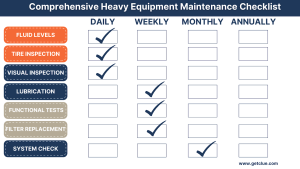

Here you will learn basic maintenance, like checking oil levels, greasing joints, inspecting tracks and tires, and reporting anything unusual. You don’t need to be a mechanic but knowing the signs of a machine in trouble will make you stand out.

Skills you’ll develop:

• Preventive maintenance habits

• Detecting early warning signs

• Reporting and documenting issues properly