🛠 Behind the Training Yard: By Next Gen., Special Correspondent

KAMPALA – The weather is really hot. A deep rumble fills the air as a young man, no more than 22, comprehends the controls of a large excavator. His helmet shifts slightly. His eyes are fixed.

An older man with a brilliant vest stands next him, arms folded and gaze fixed on every action.

He does not speak. Not yet. He waits until the bucket scoops neatly and lands its contents without spilling.

Then, a tiny nod. That is all the incentive the young operator requires.

What’s happening here? And why does it matter?

Welcome to the training yard, where actual operators are created, not simply trained. This is where industry experts – men and women with decades of field experience – pass on their knowledge, instincts, and discipline to the next generation.

In this article, I’ll show you how skilled trainers transform trainees into self-assured, safety-conscious, and job-ready machine operators.

Whether you’re new to the field, a site supervisor, or simply interested about what it takes to operate a 30-ton bulldozer, this article is for you.

👷🏽 Why Training Yards Are More Than Classrooms

Forget everything you’ve heard about sitting in a classroom with outdated guides. Today’s operator training programs combine hands-on equipment experience with realistic scenarios.

At Next Gen, I met Grace N, a former roadwork engineer turned trainer.

“The field is not forgiving,” she advised me. “We teach trainees what might go wrong before it happens. It’s more than simply buttons and levers; it’s about judgment, accountability, and pride.”

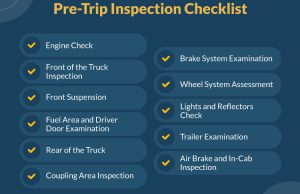

This attitude is at the core of modern operator training. Students learn everything from:

• Basic machine components

• Pre-operation inspection routines

• Machine-specific maneuvers (e.g., trenching with an excavator or grading a slope)

• Emergency response drills

🛠️ How Experts Turn Mistakes into Mastery

Real learning comes from making little mistakes in front of the right people, not from achieving perfection.

Consider the incident of John, a student who mistakenly tipped a motor grader too far down a slope. It was a scary moment. The engine groaned. Everyone froze.

Instead of yelling at the teacher gently stepped aboard, pointed out the error, and showed John how to recover.

“We expect fear. “That is normal,” the trainer explained. “But fear becomes confidence when you teach people how to react, not just what to do.”

Every mistake in the training yard serves as a learning opportunity. Every lesson is a step toward greater confidence.

📉 Why Skipping Training Is a Dangerous Shortcut

Let’s get real: Some people think they can skip formal training because they’ve “sat in the seat before.” But operators who jump straight into real jobs without proper training end up:

• Damaging expensive machines

• Causing job site delays

• Endangering themselves and others

🚨 According to OSHA, 30% of all heavy equipment incidents involve untrained or improperly trained operators.

💬 The Trainer-Trainee Bond Is Key

What impressed me most about the training yard was the peaceful trust between instructor and trainee.

Grace describes it as “building confidence through closeness.”

She understands each student’s talents, worries, and development.

“When a student finally nails a perfect grade or scoops like a pro,” she told me with a grin, “you can see it in their face – they know they belong in that machine.”

The human connection is what distinguishes great training from mechanical routines.