7 Heavy Machinery Tips: Do You Think You Know it All?

You will learn how to work on the early shift on a remote construction site, operating a bulldozer. You will also learn what happens when you skip the quick terrain check when you decide to start your training.

So today, you will learn 7 real, practical heavy machinery tips that could save your time, your equipment and maybe even your life wherever you are bit it in Uganda, Congo, Burundi, South Sudan and more.

Tip 1: Always Inspect Before You Start

Before you touch a control or turn the key, walk around the machine every single time. Look for: Fluid leaks, Damaged hoses, Loose bolts and Worn-out tracks or tires. It might take you five minutes. But skipping it can cost thousands in repairs or worse.

Tip 2: Respect the Ground You’re On

The ground can look dry and stable… until it’s not and take time to; Assess soil conditions, look for sinkholes or soft spots and Stay alert on slopes or wet areas. I once watched an excavator tip just because someone assumed the ground was firm. Don’t assume. Always check.

Tip 3: Keep Movements Smooth and Steady

You will learn how jerky controls are a rookie move, a great operator moves with accuracy and therefore use the following; Gentle joystick and pedal control, Slow, deliberate turning and Measured lifting and dumping.

Because It saves fuel, reduces machine wear, and keeps everyone safer. And trust me everyone notices the operator who handles the machine like an extension of their body.

Tip 4: Know Your Machine’s Limits

Every machine has a limit don’t test it that is Overloading, speeding, or forcing the machine to do more than it’s built for will and these leads to break hydraulics, damage the engine and risk tipping or failure.

Always check; Load capacity, swing radius, ground clearance and use the machine for what it’s built to do, not what you think it can handle.

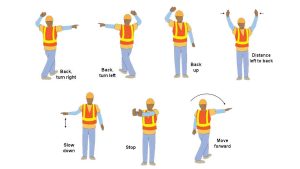

Tip 5: Communication is Not Optional

One of the biggest causes of accidents on a site? Poor communication. Whether it’s through radio, hand signals, or just shouting across a short distance, clear instructions save lives.

Therefore, establish signals with: spotters, truck drivers and ground crew. And remember if something feels unclear stop everything and ask.